"Building the best arrows" By Jack Wallace

/This Tech Tip will cover how I build all my arrows. It may be similar to other things you’ve heard, but some things you catch and pick up on can put a point or two on your scoreboard.

I’ll start by taking one full dozen shafts and a cleaner with any small cleaning swab like a 22-rifle cleaning rod, miniature bore snake, or almost anything that will fit through the shaft. Last Chance offers a great bore brush & swab kit called the Precision Arrow Prep Kit that would work great and cover various shaft sizes. Then, I will clean the inside of the shafts with water, acetone, or alcohol. I do this because you’ll often see inside carbon arrows some residue, dust, or something inside the shaft. I will quickly run a single pass through each shaft and ensure they look like a mirror inside.

Next, I’ll weigh out all 12 shafts, and somewhere in the center of the shaft (where I won’t be cutting, cleaning, or fletching), I’ll write a number on the shaft. I will write the numbers 1 through 12, 1 being the lightest and 12 being the heaviest. I then lay out a dozen of the bushings I will shoot. I’ll check the weight and make sure there’s no noticeable variance. I’ll lay out one dozen points. I will weigh all the points and number them on the shank of the point 1 through 12 from lightest to heaviest (you can probably see now where I’m going with this) I will install my bushings. I will install my nocks. I will cut the shaft to the correct length and square them. Next, I’ll clean out all the carbon dust inside the shaft with a cotton swab soaked in water.

At that point, I can lay out those 12 shafts and points numbered 1 through 12 (lightest to heaviest), and I will take the number 12 point and put it in the number 1 shaft. I’ll put the number 11 point in the number 2 shaft. The number 10 is in number 3, and so on, until number 1 goes into number 12. I’m putting together the heaviest points and the lighter shafts to eliminate as much variance as possible. The next part of my build process is how I fletch the arrows.

I will take an acetone-soaked rag and clean the shafts where the vanes will be. I will then clean the same area with a cloth soaked in water. I’ll take the vanes I’m using and do nearly the same thing. I’ll take an acetone-soaked rag and place a vane in a clamp. I’ll clean the base of the vane thoroughly. I will then wipe the vane with water. I’ll then take my priming pen, clean the vane base, immediately apply my glue, and apply the fletching to the shaft. While leaving that vane gluing, I will take an extra second clamp, place another vane in it, and do the cleaning process. I will clean it with the acetone and then the water, but I will remove it from that clamp. I’ll take the clamp off that’s on the arrow and place the cleaned vane in it. I’ll hit it with a priming pen, then immediately add glue and apply it to the shaft. This way, I’m always cleaning one vane and prepping it while waiting for the next one to go on. It lets the process go just a little faster and a little smoother. When one arrow is fully fletched, I will remove it from the jig and put a small droplet of glue at each vane's front and back base. With proper cleaning and drying time, my vanes will not come off of my arrows.

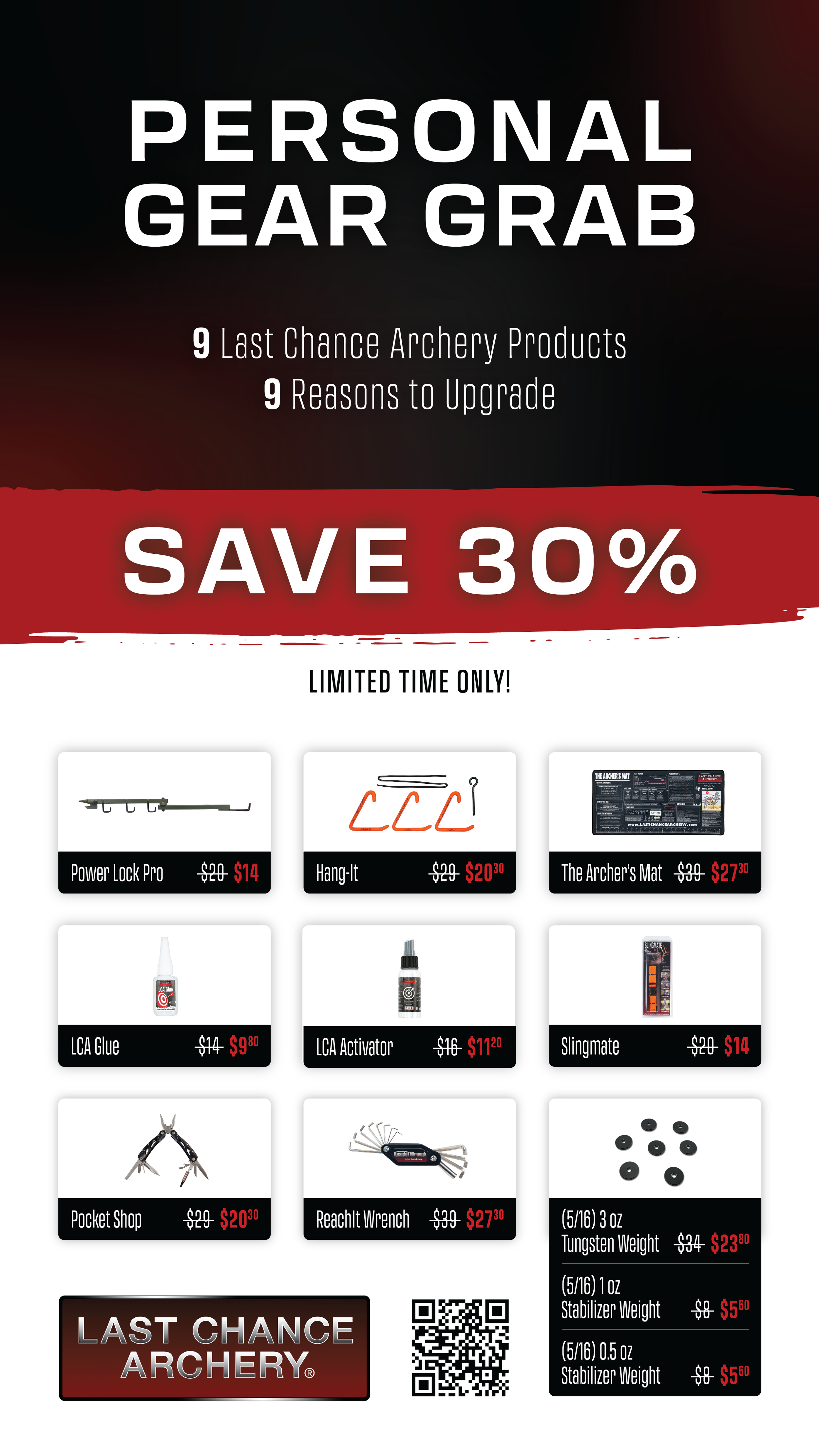

Once all this is finished and done, I will have 12 arrows that will not vary a grain, and everything will be built and controlled as well as possible. I hope these tips help you build the best-finished arrows you possibly can. The Last Chance Archery products listed below are the ones I use to build arrows the way I’ve just described.